Plenty of industries rely on fabricated parts, but few require the precision and flawless design of aerospace components. In this industry, mass finishing solutions play a vital role in creating the durable, intricate pieces that complex aircraft depend on. They can also offer manufacturing benefits like efficiency, consistency and reduced waste.

Let’s take a closer look at mass finishing equipment for the aerospace industry and how it affects manufacturing.

Finishing refers to a wide range of tasks used to improve the surface of a part, such as applying coatings, polishing metal, removing defects or adding metal plating. Virtually all metal parts go through this process, as do many non-metal parts, like plastics and ceramics. While finishing methods can vary widely, the end goal is typically to ensure the part can better perform its job, meet specifications and take on a better appearance.

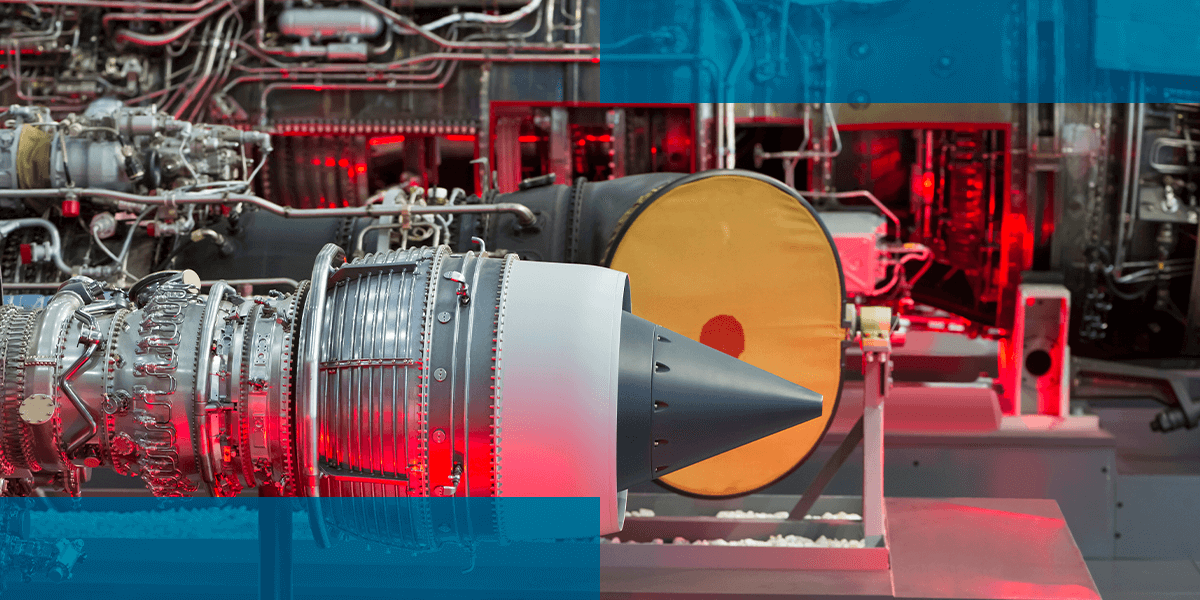

In aerospace, finishing is generally aimed at making the parts smooth and polished and removing any surface inconsistencies from the fabrication process. For example, metal casting or machining might leave seams or burrs on the part that could hurt performance and create a sloppy appearance. Finishing solutions can remove those seams and burrs while polishing up the edges and making the part shine.

When various finishing systems come together or support many parts, we call the process mass finishing. It’s commonly used in manufacturing, especially where complex parts with tight tolerances are involved. Mass finishing helps deliver repeatable, dependable results to many parts.

In the aerospace industry, the stakes tend to be higher, with complicated machinery, strict regulations and severe consequences for malfunctions.

Aerospace equipment must stand up to rough atmospheric conditions, evolve to meet changing emissions and efficiency standards and offer a safe, enjoyable experience for everyone on board. None of that can happen without reliable components, and aircraft require many of them. Even a small plane could have millions of parts, all of which must work together cohesively to mitigate risk as much as possible.

Mass finishing helps these components attach to each other and improve performance. If any one of them fails or jams up, it can lead to catastrophic results. Mass finishing helps avoid these repercussions by removing surface defects and creating a completely smooth surface, so parts can function as intended. Blades keep spinning, coatings stay protective and nozzles keep pumping.

Some examples of parts that benefit from mass finishing include:

Finishing methods can accomplish a range of goals simultaneously, like deburring, polishing, descaling and edge-breaking.

The list of finishing equipment is extensive and can cover diverse elements of a part’s appearance and performance. Some types of mass finishing equipment solutions include:

Metal finishing for aerospace components can help you meet an array of goals. Some of the advantages of parts finishing equipment for the aerospace industry include:

Whether your goals center around the product or the manufacturing process, mass finishing equipment can make a considerable difference.

As a vital part of the aerospace industry, mass finishing solutions should come from a dependable partner. At New England Sales, we offer comprehensive services, such as customized consultations, a vast product selection and ongoing support, including maintenance and repairs.

We bring local expertise to businesses across the New England area. We can visit your facility and help implement the ideal solution to meet your unique needs, from space limitations to budgetary concerns.

To learn more, reach out to us today and request a quote, set up a consultation or chat with a team member.