Our HT turbine agitators have earned a worldwide reputation for their long life, flexibility, and durability, making them the preferred agitators for harsh, demanding environments where peak performance is integral.

A global market leader in the manufacture of standard and custom fluid agitation & mixing equipment and systems. 70+ years of experience.

Products include Chemineer top-entering & side-entering agitators/mixers, Kenics static mixers, Greerco high shear mixers and Prochem side-entering agitators for use in a variety of applications from small pilot scale to large production units. Agitator/mixer designs include top & side-entering right angle and parallel shaft units, gear reduced, direct drive, & air driven designs.

We enhance the efficiency and profitability of your business with our process expertise and innovative technology. From wastewater to chemical processing, pharmaceuticals, and other industrial applications, we work with you from the start to develop integrated solutions with superior performance — maximizing your project lifecycle.

Finding the correct equipment for your operations will require understanding how different equipment works and how they better fit your needs. Here are some of the applications and industries using Chemineer mixing equipment:

Products include Chemineer HT heavy duty right-angle turbine agitators, model 20 HT/GT Series rugged vertical & right-angle drives, MR parallel shaft, helical gear drive, QED Plus economical, top-entering mixers.

Our HT turbine agitators have earned a worldwide reputation for their long life, flexibility, and durability, making them the preferred agitators for harsh, demanding environments where peak performance is integral.

Model 20 HT/GT Agitators Chemineer’ s 20GT/20HT series is a very rugged and versatile agitator. The 20GT/HT is available as a vertical or right-angle unit, features oversized bearings & helical gearing a dry-well seal to prevent gearbox oil leakage.

The MR agitator’s gearbox is a proprietary, parallel-shaft, helical gear design that features a minimum 30,000-hour L10 bearing life and an oversized output shaft for optimal performance and extended service life.

The Chemineer QED Plus Mixer combines Quality, Economy and Durability for unbeatable mixing value and agitator service in chemical processing, wastewater treatment and general industry applications.

Products include Chemineer DT Top-entering & portable style direct dive & gear drive mixers, XP-Express portable style clamp-mount & fixed mount mixers-electric motor & air driven designs

Chemineer offers a line of DT top-entering and portable mixers with direct-drive and gear-reduced designs for both open and closed tank applications.

Chemineer’ s XPress Portable Mixers offers quick, total support for mixing needs in the chemical and petrochemical, pharmaceutical, biotechnology, polymers and food and grain processing industries.

Chemineer’ s sanitary mixers offer a variety of design configurations, materials and options needed to meet critical sanitary mixing applications and ensure the highest level of sanitary mixing.

Products include Chemineer HS gear drive & SB belt drive side-entering agitators and Prochem PB & MD belt-driven side-entering agitators

|

|

|

|

backed by over 50 years of static mixing technology with 1000s of installations in the field.

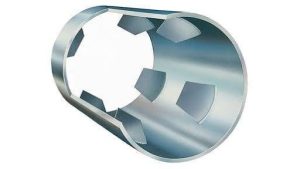

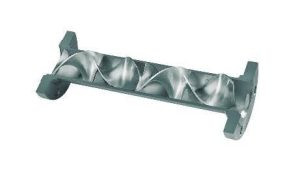

Kenics static mixers and heat exchangers utilize process specific mixing elements in a housing for continuous flow mixing, blending and heat transfer. The elements use the energy from the process stream flow to provide blending, dispersion, and heat transfer with minimal pressure (energy) loss. Kenics static mixers are available in a wide range of sizes and materials of construction.

|

|

|

|

Kenics static mixers maximize mixing efficiency without the wasted energy and material blockage typically found in more restrictive motionless mixers. KM Style mixers are available in a wide range of materials including PVC, FRP & Teflon as well as Sanitary Food & Biopharm designs.

|

|

|

Kenics Shell and tube exchangers utilize Kenics elements to boost heat transfer rates for high viscosity cooling and heating applications over conventional shell and tube heat exchangers. Kenics® Heat Exchangers, offers the highest available coefficients for fast, uniform heat transfer. Capable of reliable operation in a wide range of process applications, including those in the polymer, plastic, and food and beverage industries, Kenics Heat Exchangers require less space, less energy and less residence time than standard designs.

Ideal for larger diameter waste water treatment

Kenics HEV static mixer maximizes the conversion of turbulent energy into efficient mixing. Ideal for large diameters wastewater treatment applications. Available in alloy and non-metallic construction.

The KMX-V static mixer is the best choice for demanding mixing applications, including those involving fluids with extreme viscosity or volume ratios.

Designed for turbulent flow applications common in water treatment, desalination plants, and chemical processing, the Kenics UltraTab delivers a high degree of mixing in a compact space.

The Kenics WVM Static Mixer is used in the water and wastewater industries and offers a simple wall injection point, optimization of length vs drop parameters, improved performance at very low flow rates, and lower capex and opex.

Chemineer provides an array of impellers for a variety of applications in the chemical and petrochemical, pharmaceutical, biotechnology, polymers and food and grain processing industries.

If there were only one mixing job to do, only one impeller would be required. However, there is a very wide range of problems in agitation, and the best impeller for one application may not be the best impeller for another. The descriptions and discussions below are intended as a guide for impeller selection. Relative impeller sizes are compared to the P4 at equal horsepower and equal speed.

The highest efficiency turbulent flow impeller available in the marketplace. Ideal for blending, heat transfer, and solids suspension applications. Developed to maximize strength at lower weights as compared to other axial flow impellers, allowing for longer shafts without internal support, smaller shaft diameters, and smaller seal sizes if applicable.

An extremely efficient turbulent flow impeller for blending, heat transfer and solids suspension. Most effective for Reynolds numbers over 50. Developed to minimize the creation of trailing vortices and incorporating the otherwise wasted energy into macro-flow.

Engineered for deep tank applications utilizing rolled blade design.

The Chemineer® SC-3 Impeller features an advanced design engineered for deep tanks. It produces flow characteristics of much larger impellers, without the added weight, or the resulting loss in pumping efficiency. The highly efficient SC-3 Impeller’s reduced weight allows for the use of longer shaft extensions for deeper tanks, and resolves associated critical speed limitations. The use of an SC-3 impeller can produce an overall agitator cost savings as much as 33%.

Axial flow design suitable for wide changes in process viscosity. A cost-effective impeller in both turbulent and laminar flow. Good impeller for applications where the viscosity changes over a wide range causing the flow regime to vary between turbulent and laminar flow. A reasonably cost-effective impeller for solids suspension.

Close clearance design for operation near the tank bottom. A cost-effective impeller for operation very near the floor of a tank for agitating the heel in solids suspension applications. Also, an effective impeller in laminar flow applications, especially when impeller Reynolds numbers drop below 50.

The unique blade geometry of the BT-6 creates optimal flow conditions above and below the disc to efficiently disperse gas at even the highest flow rate.

Highest gas dispersing capability available. Can disperse nearly six times the gas handling capability of the D-6 or Rushton impeller. Unloads less than the CD-6. In fact, the unloading is nearly all due to the change in effective density of the gassed liquid. The mass transfer capability is on the order of 10% better than the CD-6. Unlike many other gas dispersing impellers, the BT-6 is relatively insensitive to viscosity.

The CD-6 impeller improves the mass transfer rate as much as 50% in gas dispersion operations. The CD-6 impeller is a second-generation gas and immiscible liquid dispersion impeller. The CD-6 can handle about 2.4 times the maximum gas capacity of the D-6 impeller.

The CD-6 is similar to the Smith impeller, but there are substantial power and dispersion capability differences. This impeller has been used at aeration numbers as high as 2.1.

Good cost-effective impeller for low concentrations of immiscible liquid or gas. Two very strong trailing vortices are shed from each blade. These areas of high shear are responsible for breaking the larger droplets to smaller droplets. Maximum aeration numbers should be limited to 0.1.

Excellent performance in abrasive solids suspension, liquid-solid-gas and boiling or near boiling applications.

The Maxflo W impeller, with about 10% more effectiveness in pumping efficiency, is an improved version and full replacement impeller for the Maxflo T. Excellent in abrasive solids suspension, solids suspension in the presence of small amounts of gas introduced or generated in situ, and in boiling or near boiling applications.

Chemineer’s impeller for side entry applications offers greatly improved efficiency and unparalleled process performance. A high efficiency, advanced side-entering hydrofoil impeller that produces maximum pumping action. It has more cavitation resistance than other designs through effective hydrodynamic design.

High efficiency, high solidity impellers for use in turbulent side entering applications. They are especially effective for fluids possessing a yield value, such as paper stock. The high solidity permits operation nearer the boiling point without cavitation.

Marine style energy efficient design.

A high efficiency turbulent flow impeller used on our smallest turbine agitators at direct drive motor speeds on our DT, BTNS and RBTNS agitator lines. The high solidity permits operation nearer the boiling point without cavitation.

Chemineer simplifies double impeller configurations for sanitary mixing processes with its patent-pending Smoothline impeller design.

It is available for the HE-3, P-4, S-4, and Maxflo W impellers. Smoothline-style impellers disassemble to pass through manways on process vessels. Their FDA-approved Teflon gaskets between every joint prevent entrapment of process material. As an added benefit, they are easily compatible with single piece shafts thus ensuring optimum straightness, efficient energy transmission and superior mixing performance.

|

|

Customize levels of shear to suit your process.

ChemShear Impellers are made in 4 different styles. Style 1 has the widest blades and style 4 the narrowest blades. Various processes require different ratios of shear and pumping. The wider blades pump more, and the narrower blades have the higher level of shear. They work well in applications which require moderately high shear but also some level of pumping. Many high shear devices are very low in pumping capability and require an auxiliary impeller to provide turnover. ChemShear impellers often overcome the need for an auxiliary pumping impeller. ChemShear impellers have been used in microencapsulation processes producing particles in the 2-micron range.

Proven the best high viscosity, laminar flow impeller.

Generally recognized as the best all around high viscosity, laminar flow impeller. It is the most efficient blender of all existing close clearance agitators.

The double flight helical ribbon impeller is also good for heat transfer and blending of liquids and solids from the surface. Generally used for applications where viscosities are ordinarily greater than 30,000 MPa.

The most economical laminar flow impeller available.

The Chemineer™ anchor impeller is most effective in squatty batches in which vertical pumping is not as important as in tall batches, and it is the easiest high-viscosity impeller onto which scrapers can be mounted for difficult heat transfer applications.

Ideal for shear sensitive, uniform blending applications (polymers).

A screw impeller produces effective high viscosity blending of shear sensitive polymers. This impeller provides good top-to-bottom turnover. Although blending is generally good, heat transfer is not as good as the close clearance high viscosity impellers. The screw impeller is suitable for fluids which are not too pseudoplastic with power law indexes less than 0.5.

Chemineer provides an array of impellers for a variety of applications in the chemical and petrochemical, pharmaceutical, biotechnology, polymers and food and grain processing industries.

The JT-2 Impeller has been developed for superior blending in transitional flow. Higher viscosity and non-Newtonian fluids make blending much more challenging. This impeller is used after conventional turbines have lost efficiency due to viscous effects and before the need for close clearance impellers.

The design promotes blending by efficiently moving material in one direction in the center of the tank and the opposite direction on the outside of the tank. The increase in efficiency of this impeller comes from the improved flow pattern that greatly reduces recirculation zones that extend the blend times of other impellers. This flow pattern improves the top to bottom communication in the vessel.

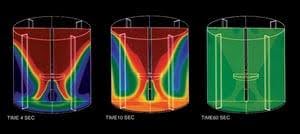

Chemineer’s CFM models receive extensive validation using advanced experimental techniques. Chemineer is the first in the industry to use laser-based Particle Image Velocimetry (PIV) for mixing analysis. The unique data obtained with PIV further improves our modeling capabilities and provides you with the most accurate design for your agitation needs.

DPIV technology instantaneously measures the entire fluid velocity field in a tank, making it possible to study large-scale, time-dependent phenomena in the tank.

Other agitation & mixing tools utilized include Laser Doppler Anemometry (LDA,) Laser-Induced Fluorescence (LIF).

Chemineer uses these measurements to verify ChemScale and characterize specific impeller zones. This information may often be used with CFM to accurately determine the flow in the mixing vessel.

|

|

|

The Chemineer Research and Development (R&D) Laboratory is in Dayton, Ohio, and is broken down into two different areas: customer testing and R&D.

Greerco High Shear mixers utilize an axial in/out rotor and stator system to provide mixing and shear in emulsion, dispersion, and colloidal applications.

Tank mounted Homogenizers or in-line Colloid Mills and Pipeline Mixers are available for your processing applications in the Food, Cosmetic, Oil and Gas, Polymer, and Chemical Processing Industries.

|

|

|

To find the best equipment for your specific needs, you need to enlist the help of a reliable and professional supplier. Durable equipment would help avoid unplanned downtime due to repairs and maintenance. For this reason, you need a distributor who understands both the equipment you need and your needs.

New England Sales offers a variety of Nov-Chemineer mixing and processing equipment for any application. Contact one of our experts today!