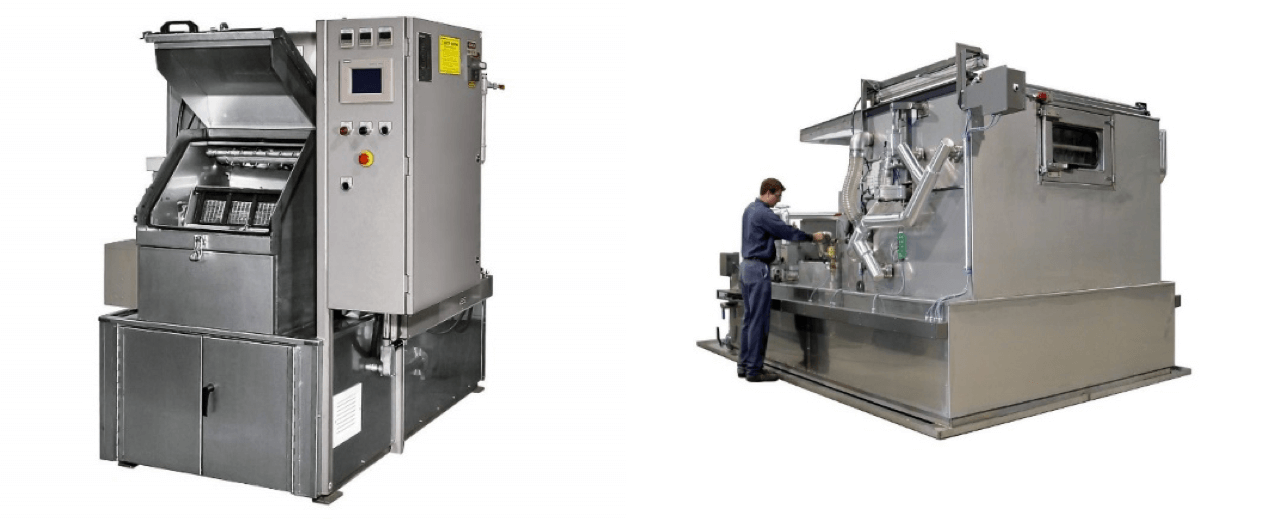

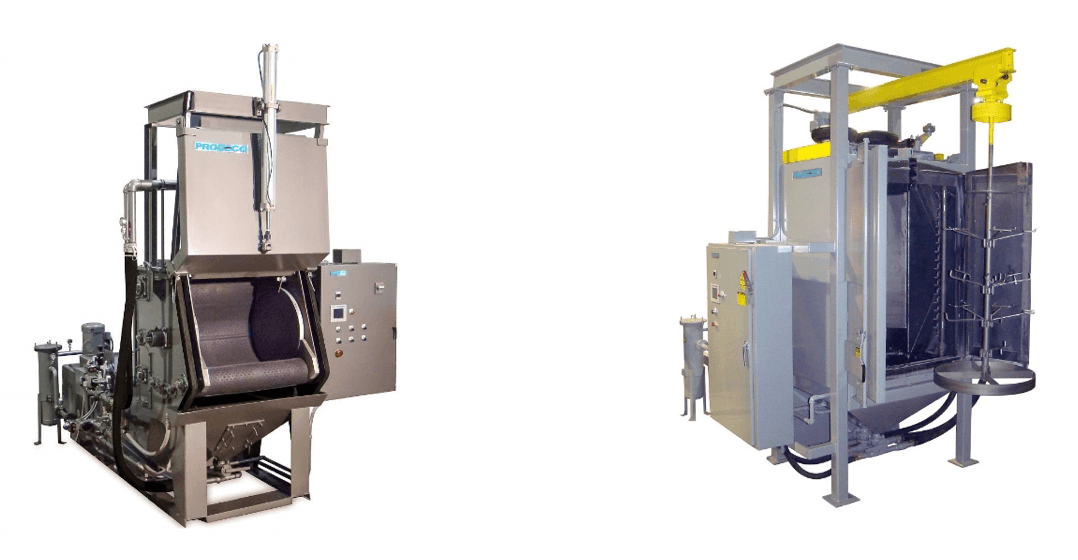

Cabinet Spray Parts Washers

- Cabinet spray washers feature a turntable which rotates workpieces through a pattern of strategically placed spray nozzles – fully enclosed in a washing cabinet.

- PROCECO offers a full line of low maintenance turntable wash systems for a variety of cleaning tasks in manufacturing, maintenance, and remanufacturing applications.

Proceco Typhoon HD Heavy Duty & Typhoon PCE Compact Ergonomic Parts Washers