The first stage of the Zero Liquid Discharge process is pretreatment and conditioning. In this step, the wastewater is filtered to remove suspended solids. The water is also conditioned during this phase to help streamline the following steps.

A Zero Liquid Discharge (ZLD) process water recycle system gives you the capability to treat wastewater and recover it for reuse. These systems are an excellent way to reduce your water footprint while meeting strict regulations for wastewater management.

At New England Sales, we offer an extensive selection of closed-loop ZLD process water recycle systems for sale, with options from the industry’s leading brands. You can count on our team to work with you and determine which machine represents your best buy.

Zero Liquid Discharge is a wastewater treatment method that treats process discharge waters, then recycles them back into your facility. This process captures fluid waste, helping to minimize your disposal costs and reduce your environmental impact.

Closed-loop Zero Liquid Discharge process water recycle systems are an innovative technology utilizing state-of-the-art machinery. In addition to water recovery, you can use them to manage variations in contamination and flow, treat and retrieve byproducts, and collect solids into a dry, solid cake for simple disposal.

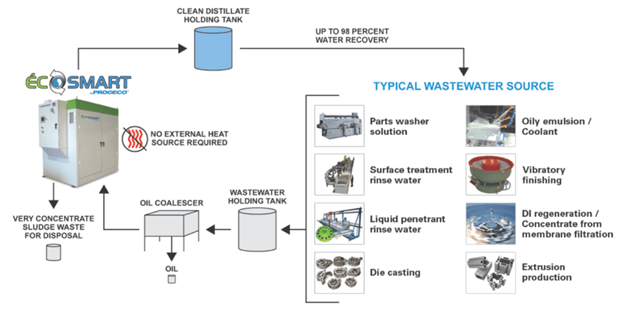

Facilities in the Northeast can get closed-loop ZLD and Proceco EcoSmart MVR recycle systems for parts washers, deburring machines, metal finishing equipment and more in different sizes and with varying capabilities. The designs and technologies used to produce them will vary by manufacturer and facility.

ZLD closed-loop rinse water recyclers do not require pre-treatment and are designed with simplified operation and maintenance in mind. We offer facilities in the Northeast ZLD recycle systems for deburring machines, parts washers, metal finishing equipment and more. These machines allow facilities to save space, time and money compared to traditional zero-liquid discharge systems.

The energy-efficient Proceco EcoSmart MVR follows the traditional rinse water process and is ideal for dealing with oily or dirty part washer waters. The Proceco Ecosmart MVR uses the following steps:

The first stage of the Zero Liquid Discharge process is pretreatment and conditioning. In this step, the wastewater is filtered to remove suspended solids. The water is also conditioned during this phase to help streamline the following steps.

The next stage is concentration. This step usually completes using reverse osmosis, electrodialysis or brine concentration, depending on the machine. The technology takes the stream and concentrates it to higher salinity while removing most of the water.

The final step is to collect removed contaminants for disposal. Here, the remaining water is separated and pulled away for reuse using thermal processes. The leftover solids will remain in a crystallized form where they’re easily filtered out.

Selecting a closed-loop ZLD process water recycle system is a complex decision. This is true whether you’re looking to overcome regulatory challenges, practice better environmental stewardship or lower costs.

The most important things to consider when selecting a ZLD system for any business include:

Talk to our team for assistance making your choice. We’re familiar with industrial demands for businesses in the Northeast and can make system selection easy with expert guidance and a skilled recommendation.

New England Sales is your home for an extensive selection of closed-loop ZLD process water recycle systems throughout the Northeast. If you have a business or facility in RI, MA, VT, CT, NH, NY or anywhere in New England, talk to our team. We’ll show you how our company can help you become more productive, efficient and profitable with the area’s best selection and expert product guidance.

Connect with a professional today to get an estimate or request more information. Message us using our contact form and we’ll get back to you as soon as we can.